- HOME

- Solution

- Artificial Intelligence

Artificial Intelligence

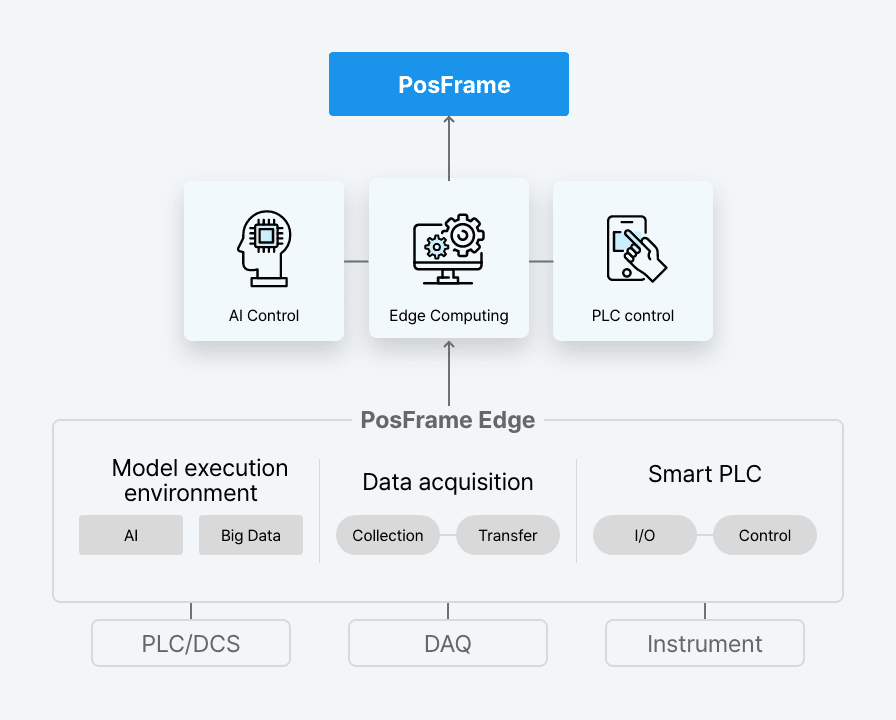

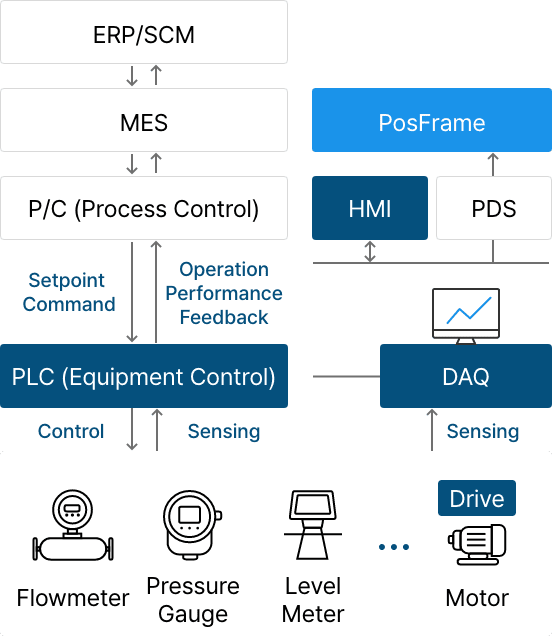

POSCO DX provides differentiated industrial AI-based services for field efficiency, autonomy, and unmanned operation through a systematic approach with the convergence of HW and OT.

Spatial Intelligence

Realizing unmanned manufacturing sites by implementing Physical AI based on self-developed deep learning architecture, utilizing field-specific data collected through key sensors installed in manufacturing sites such as LiDAR, Smart CCTV, and ToF.

- Control convergence technology

Promoting unmanned facilities through the integration of robot and PLC control and vision technology

-

- Reference

-

- Hanjin Express Vision AI-enabled real-time parcel classification

- Equipping steel unmanned mobile equipment using smart CCTVs with AI-enabled Foolproof

- Unmaned through detection of 4-continuous cast slab meandering, etc.

- 2,4-wire product inner/outer diameter shape measurement technology

- Foolproof-based unmanned safety environment application technology

- Sensor technology fusion

Securing multi-modal (Vision+X) technology to overcome limitations from a single fixed sensor

-

- Reference

-

- center point estimation technology for unmanned wire cranes

- slurry yard mapping technology using LiDAR

- Applying load estimation AI model to estimate loading & unloading times of Hanjin Express vehicles

- Product shape recognition technology for unmanned backplate cranes

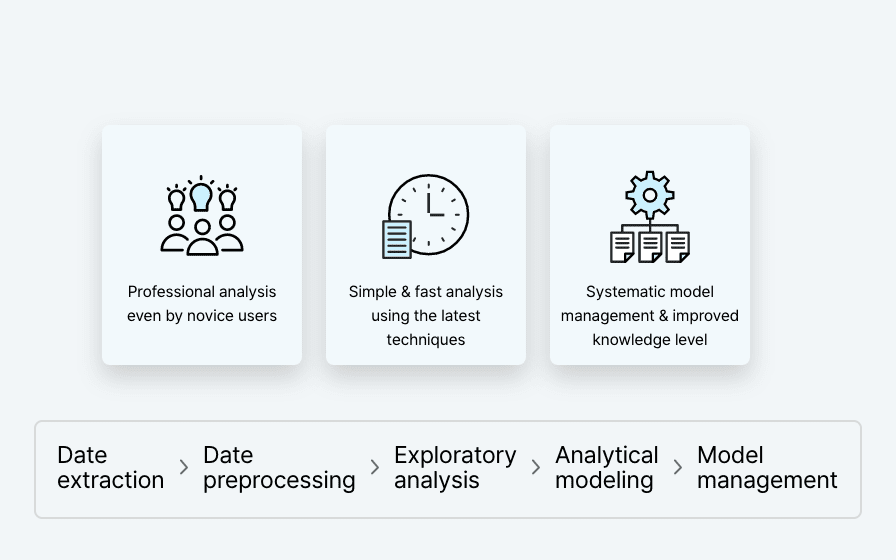

Data Intelligence

Technology that identifies abnormal behavior or abnormal data that deviates from normal patterns from sensors or log data in the manufacturing field

- Detection of facility anomalies based on sensor data

Conducting predictive maintenance by applying AI technology to rotating equipment

-

- Reference

-

- Application of AI to detect anomalies in hot rolling process ROT equipment

- Detection of anode material process motor-pump equipment anomalies

- Developing facility status data smart monitoring technology

- Detection of operational anomalies based on log data

Early detection of anormal signs based on log data generated from the operation system

-

- Reference

-

- Rolling/plating roll unit work schedule optimization

- Replacement combination schedule optimization for rolling roll inventory reduction

- Small lot order prediction and width group optimization

- LNG Spot purchase optimization

Decision Intelligence

Utilizing AI-enabled and optimization technology to facilitate data analysis & rational decision-making and applying it as technology for automation and unmanned manufacturing processes

- Process control optimization

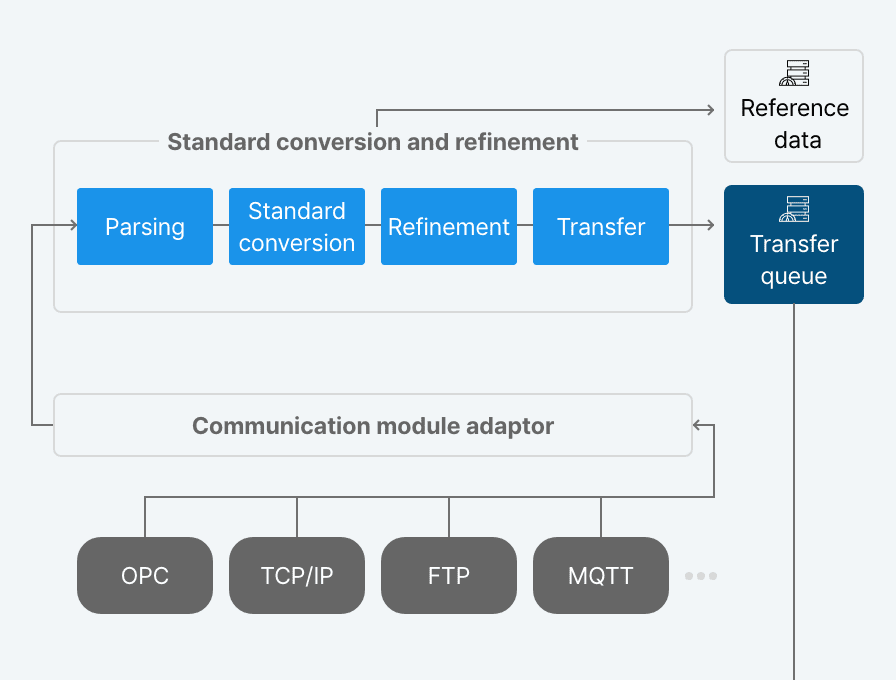

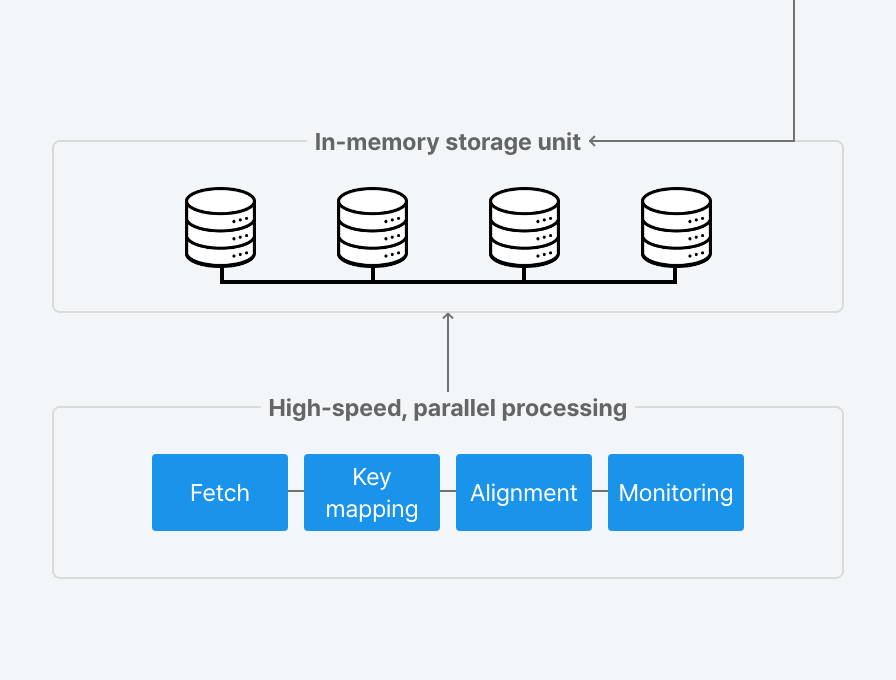

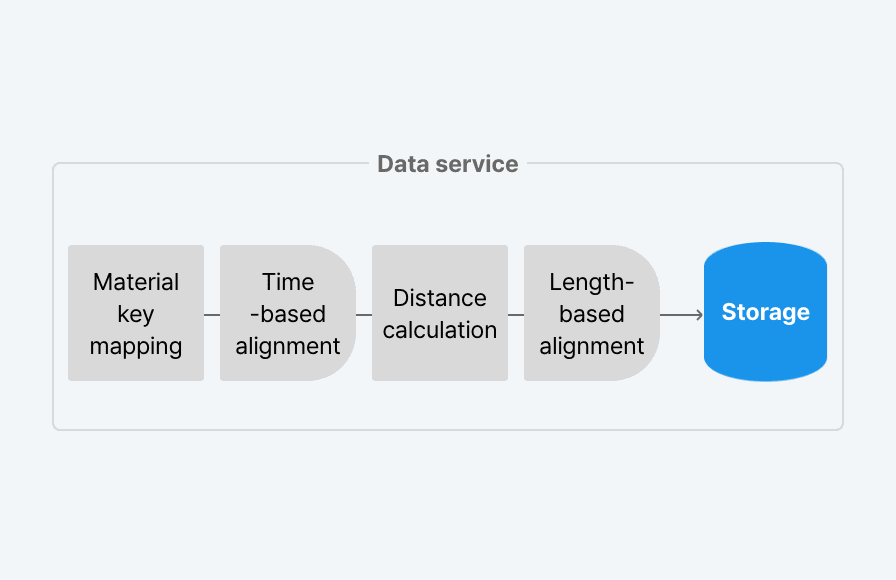

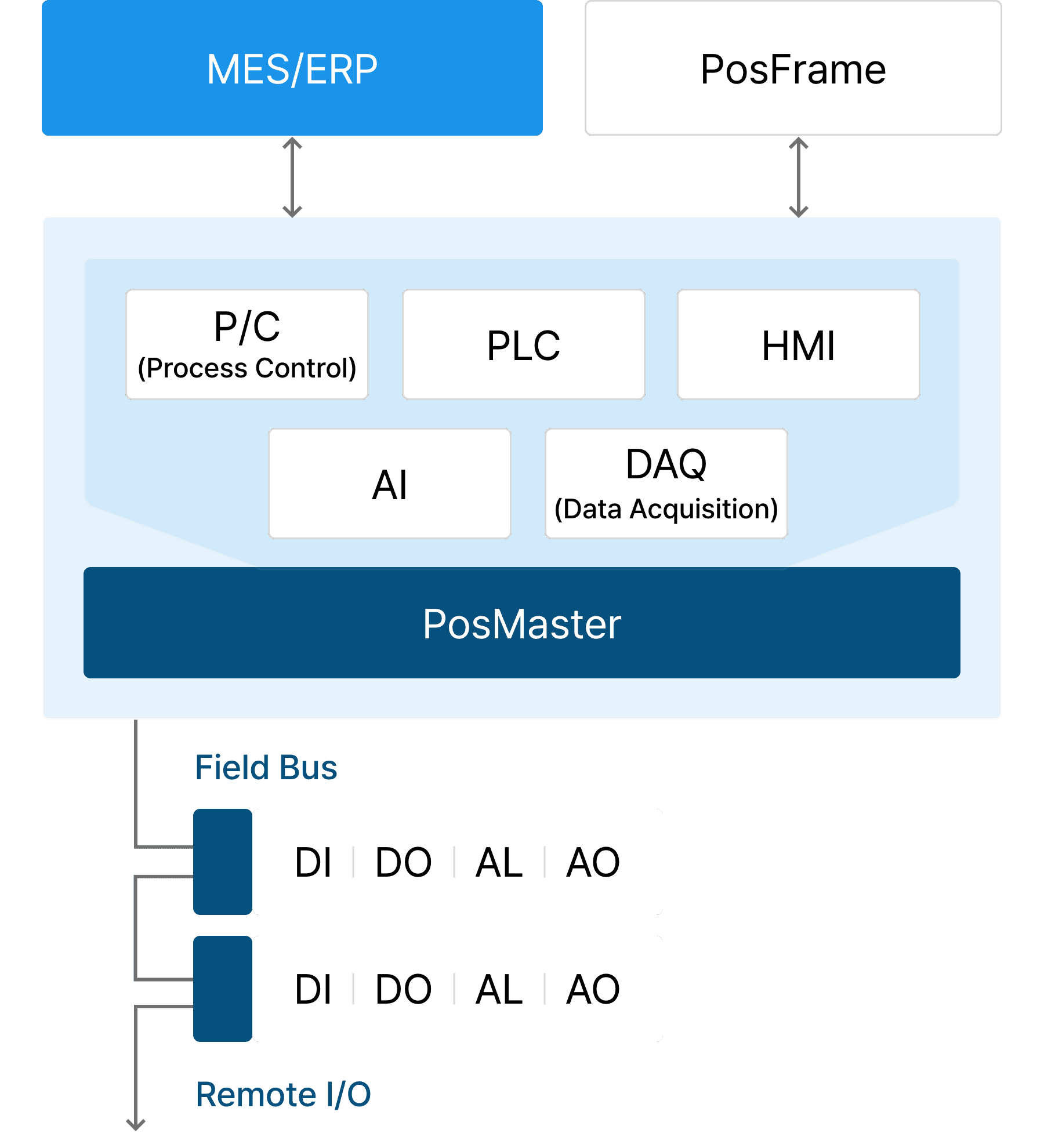

Real-time monitoring and control of the production process using sensors & algorithms

-

- Reference

-

- Optimal control of coke oven NOx reduction

- Unmanned purchase control of backplate crane

- Combination/Schedule Optimization

Technology that automates simple and repetitive tasks using agents and assists or replaces the role of developers.

-

- Reference

-

- Rolling/plating roll unit work schedule optimization

- Replacement combination schedule optimization for rolling roll inventory reduction

- Small lot order prediction and width group optimization

- LNG Spot purchase optimization

Agentic Intelligence

AI agent specialized in the steel industry by collecting and learning industrial domain knowledge of steel mills and POSCO Group companies

- Manufacturing sector

Providing manufacturing site failover response support & field work support services

-

- Reference

-

- Steel mill steel domain-based MES CC failover support

- Onsite safety management support

- Project execution PM, PMO support

- General management

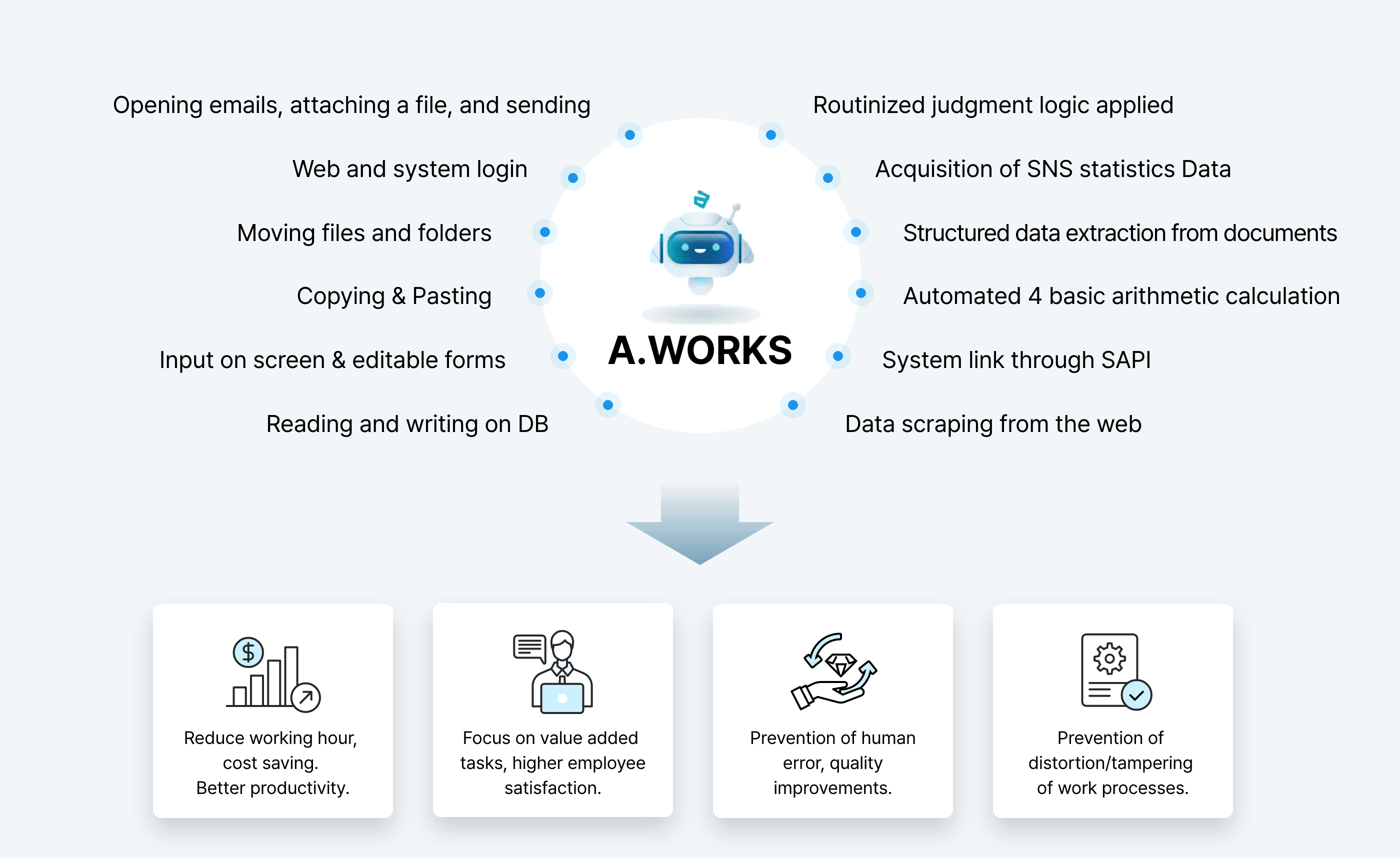

Technology that automates simple and repetitive tasks using agents and assists or replaces the role of developers

-

- Reference

-

- Q&A on company regulations, systems, & processes

- Email writing and translation, meeting minutes summary, AI-based collaboration tools, etc.

- Document analysis and OCR-based data extraction